The Advantages of Using Masterbatch in the Polymer Industry

The world of plastics manufacturing is constantly evolving, and innovations in materials and processes play a crucial role in meeting the demands of various industries. One such innovation is the use of masterbatch, a solid additive that has become indispensable in the polymer industry. In this blog, we’ll explore what masterbatch is and delve into the numerous advantages it offers to manufacturers and processors.

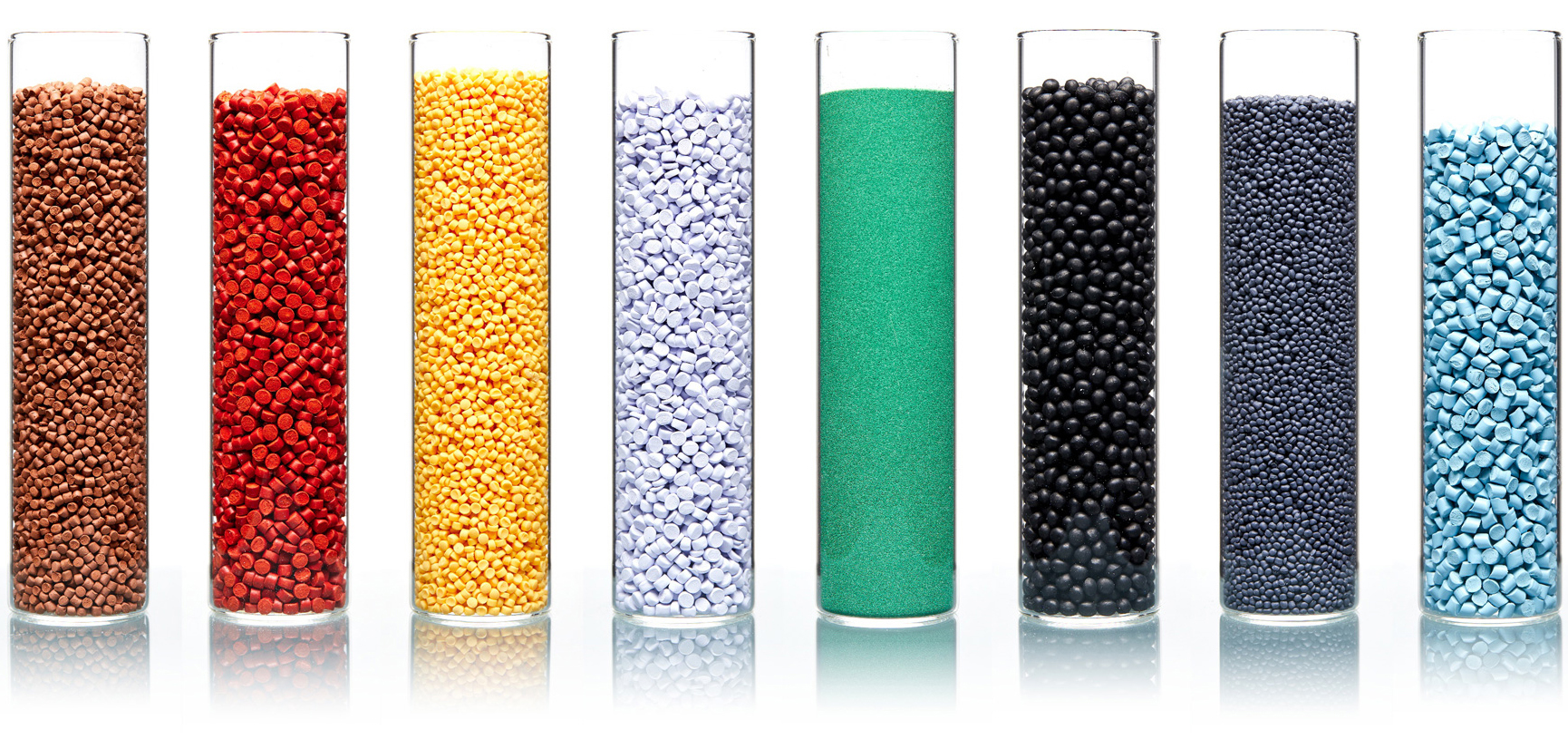

What is Masterbatch?

A masterbatch (MB) is a solid additive used for colouring (colour masterbatch) or imparting other properties (additive masterbatch) to plastics. These masterbatches are concentrated mixtures of pigments and/or additives encapsulated in a carrier matrix, such as resin or wax. The resulting mixture is cooled and processed into granules or left as a bulk solid. Masterbatches are designed to make colouring plastics more cost-effective for secondary processors.

Advantages of Using Masterbatch

1. Improved Dispersion

One of the significant challenges in polymer processing is ensuring even dispersion of additives or colorants throughout the material. Masterbatches solve this problem by providing a premixed composition with proper dispersion. This ensures uniform colouration and consistent property enhancement in the final product.

2. Cost Efficiency

Masterbatches offer cost savings in multiple ways. Manufacturers can keep stock of fewer polymer grades and purchase bulk quantities of natural polymers at lower costs. The concentrated nature of masterbatches allows for higher accuracy when dosing expensive additives, reducing waste and overall production costs.

3. High Let-Down Ratios

Masterbatches are highly concentrated, with the potential for high “let-down ratios.” For example, 25 kg of masterbatch can be used to compound one ton of natural polymer. This dilute nature makes them ideal for accurately dosing small amounts of additives, enhancing both cost-efficiency and precision in production.

4. Extended Shelf Life

Solid masterbatches are solvent-free, which means they have longer shelf lives compared to additives in liquid form. There’s no risk of solvent evaporation, ensuring the masterbatch retains its properties over time.

5. Versatility in Application

Masterbatches can be used in most polymer processing methods, making them versatile for various manufacturing processes. Whether it’s injection moulding, extrusion, or blow molding, masterbatches can be incorporated to enhance properties and aesthetics.

6. Customisation

Manufacturers can tailor masterbatches to their specific requirements. This customisation allows for the creation of unique colour shades or the incorporation of specialised additives to meet the demands of different industries and applications.

7. Improved Physical Properties

Masterbatch can significantly enhance the physical properties of plastic products. These improvements include increased toughness, flexural stiffness, adhesion, printability, and even permanent electrical conductivity when required.

8. Process Efficiency

Using masterbatch simplifies the manufacturing process by eliminating the need for on-site compounding from raw materials. This streamlines production, reduces labour costs, and minimises the risk of errors in compounding.

In the ever-evolving polymer industry, masterbatch has emerged as a game-changer, offering a multitude of advantages to manufacturers. From cost savings and improved dispersion to enhanced physical properties and customisation options, masterbatch has proven to be a valuable asset in achieving higher efficiency and quality in polymer processing. As technology continues to advance, it’s likely that masterbatch will play an even more critical role in shaping the future of plastics manufacturing.